Home>Blog>What is the difference between the pretreatment process before oil production by pressing and solvent extraction process

Home>Blog>What is the difference between the pretreatment process before oil production by pressing and solvent extraction process

What is the difference between the pretreatment process before oil production by pressing and solvent extraction process

FAQ / Chat on line / Give me a price / Date:February 26, 2025

The most common methods of processing edible oil are pressing and solvent extraction to produce oil. The extraction methods of these two edible oils are both extracted from oilseeds, but the characteristics of different oils are different, and the processes used are different, so the cost and oil yield are also different. There are some differences between the pretreatment process before pressing oil and the leaching process, mainly in the degree of crushing, temperature regulation, equipment used. The following is a brief introduction to the difference between the pretreatment process before oil production by pressing and solvent extraction process.

Crushing Degree

Pressing Process: The materials are usually crushed to a moderate extent in the pretreatment process before oil production. For example, soybeans are crushed into particles of uniform size, which is convenient for subsequent softening, rolling and pressing. The crushed particles are required to have a certain particle size to ensure that the oil can be squeezed out smoothly during the pressing process, and at the same time, a certain cake strength is maintained for subsequent treatment.

Solvent Extraction Process: The materials need to be crushed more finely. Finer crushing can increase the contact area between the materials and the solvent, improve the permeability of the solvent, and make the solvent fully penetrate into the interior of the materials to dissolve the oil, so as to improve the extraction efficiency.

Moisture Content Adjustment

Pressing Process: The moisture content of the materials is adjusted to an appropriate level to make the materials have better plasticity and fluidity during the pressing process, which is beneficial to the extrusion of oil. If the moisture content is too high, the oil quality may be affected and the cake is not easy to form; if the moisture content is too low, the oil yield may be reduced and the equipment wear may be aggravated.

Solvent Extraction Process: The moisture content of the materials is usually required to be lower than that of the pressing process. Low moisture content can prevent the hydrolysis of oil, reduce the viscosity of the solvent and oil mixture, and is conducive to the extraction and separation of the solvent and oil. It also helps to avoid the growth of microorganisms and the deterioration of materials during the extraction process. This is one of the key differences between pretreatment process and solvent extraction process.

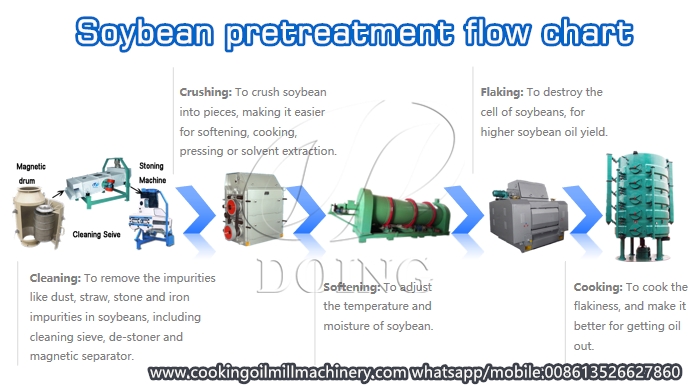

Soybean pretreatment process

Soybean pretreatment process

Temperature Control

Pressing Process: The temperature of the materials before pressing is generally controlled at a relatively moderate level. For example, in the production of soybean oil, the temperature of the materials is usually around 100°C. Appropriate temperature can make the oil in the materials have better fluidity and is easy to be squeezed out, while avoiding excessive temperature causing the denaturation of proteins and other substances in the materials and affecting the quality of oil and cake.

Solvent Extraction Process: The temperature of the materials in the pretreatment of solvent extraction is relatively high. Higher temperature can not only improve the fluidity of oil, but also accelerate the diffusion rate of solvent in the materials, enhance the extraction effect of solvent on oil, and improve the extraction efficiency.

Equipment Used

Pressing Process: The main equipment includes cleaning equipment, crusher, softener, flaker and steaming and frying pan. The cleaning equipment is used to remove impurities in the raw materials; the crusher is used to crush the materials into particles; the softener adjusts the moisture and temperature of the materials; the flaker presses the crushed materials into thin slices; the steaming and frying pan further changes the internal structure of the materials to improve the oil yield.

Solvent Extraction Process: In addition to the basic equipment such as cleaning equipment, crusher, softener and flaker, a bulker is also needed to change the internal structure of the materials and make them porous, so as to facilitate the penetration of the solvent. Since the bulker is added, a plate dryer is also required to ensure that the moisture content of the materials is within a suitable range.

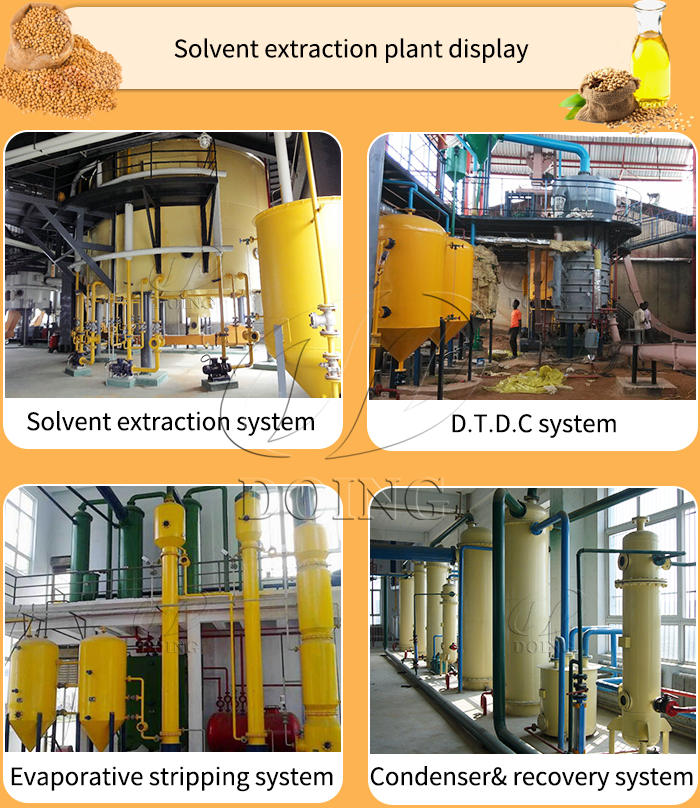

Solvent extraction process

Solvent extraction process

Purpose Emphasis

Pressing Process: The pretreatment of the pressing process is mainly to improve the physical compressibility of the materials, so that the oil can be effectively squeezed out during the pressing process, and to ensure the quality of theoil and the formability of the cake, so as to facilitate the subsequent treatment of the cake

Solvent Extraction Process: The focus is to improve the permeabilitfficiency extraction of oil, and improve the oil yield and the quality of the meal.

The above is an introduction to the difference between the pretreatment process before oil production by pressing and solvent extraction process. If you want to learn more about cooking oil extraction methods or how to choose equipment for extracting cooking oil, please contact us. As a professional manufacturer of cooking oil extraction equipment, Henan Glory company will provide customized services according to your requirements.

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line